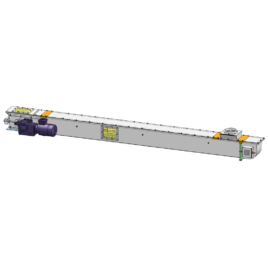

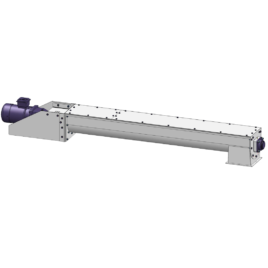

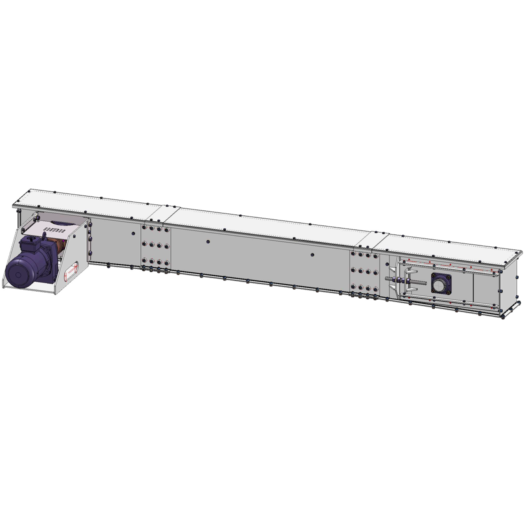

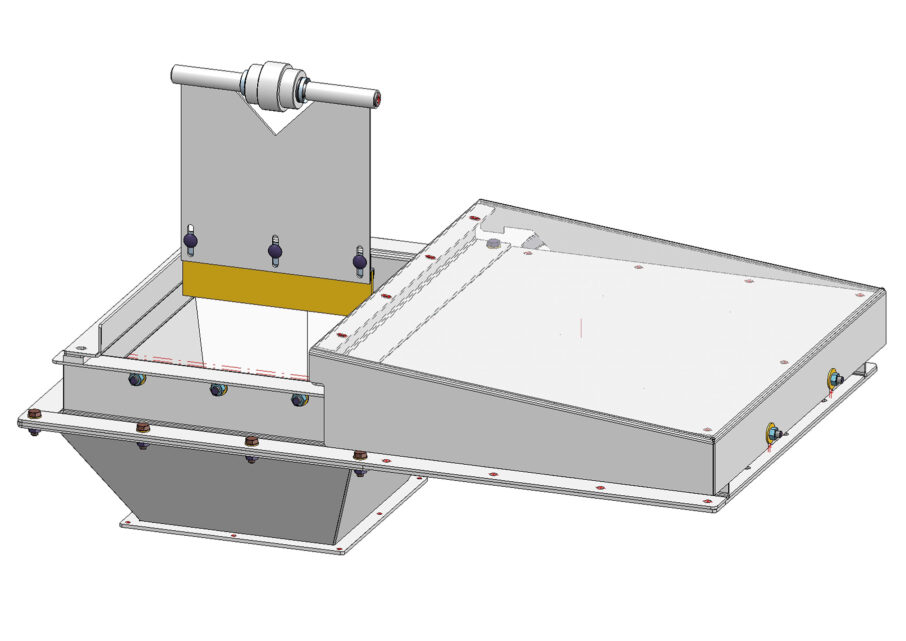

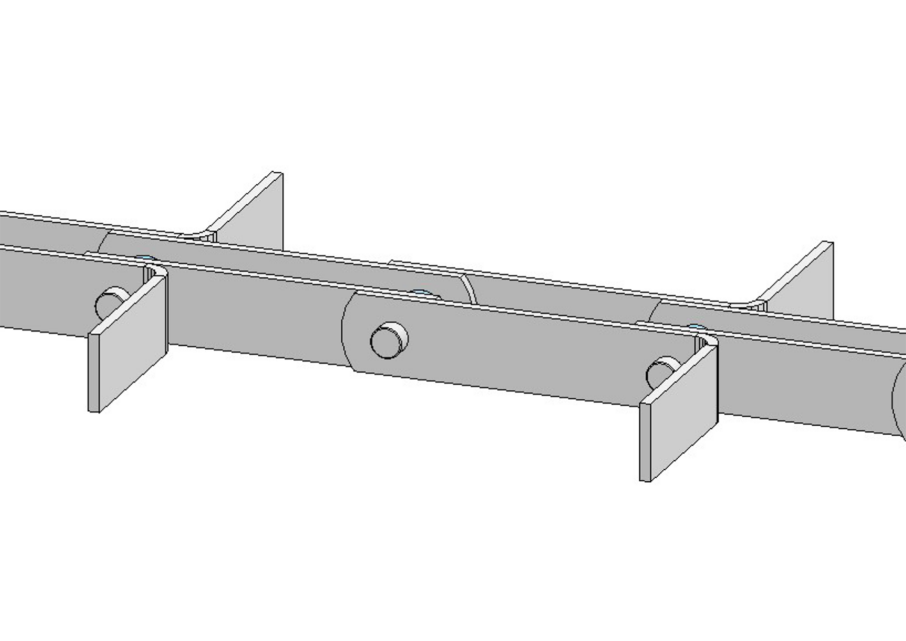

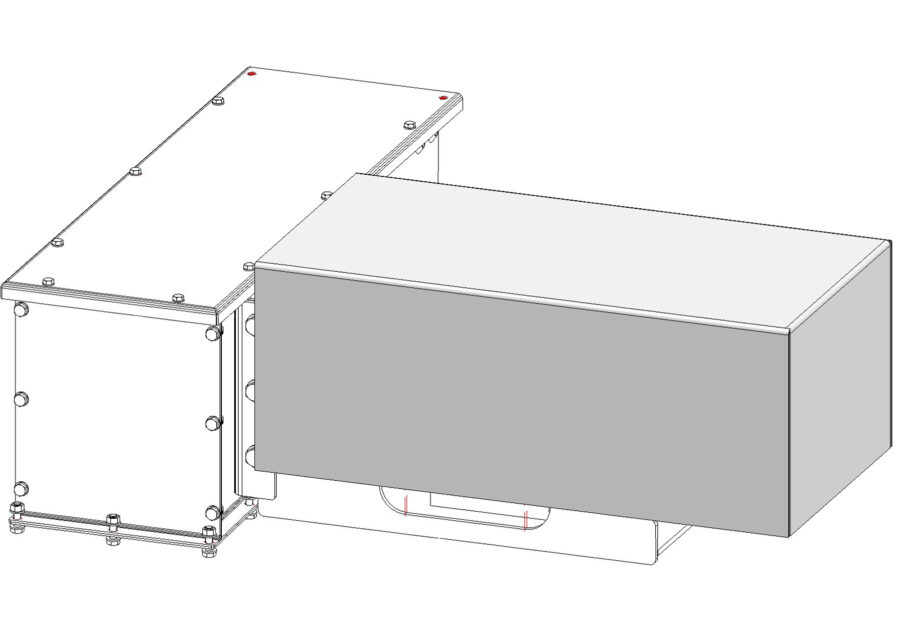

Trough chain conveyors

for horizontal transport or transport on a slight upward incline

Chain conveyors transport floury, grainy and lumpy bulk materials horizontally or on a slight upward incline. Chain conveyors can also be used as intake chain conveyors and for silo discharge.

Starting with our standard modular-system we adapt the chain conveyor to the product characteristics, the installation situation and the process requirements.

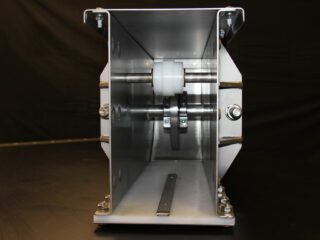

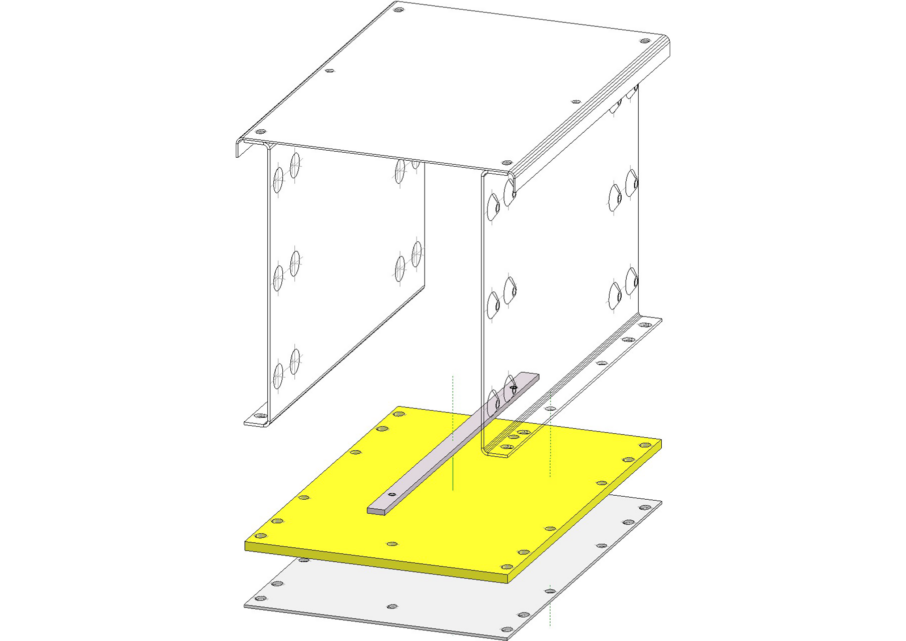

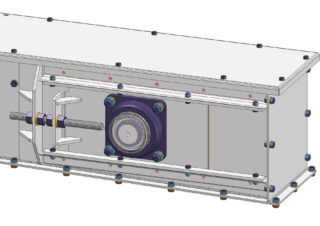

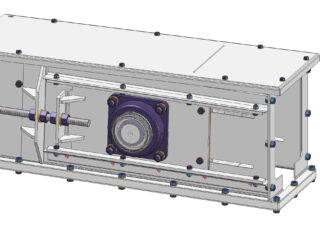

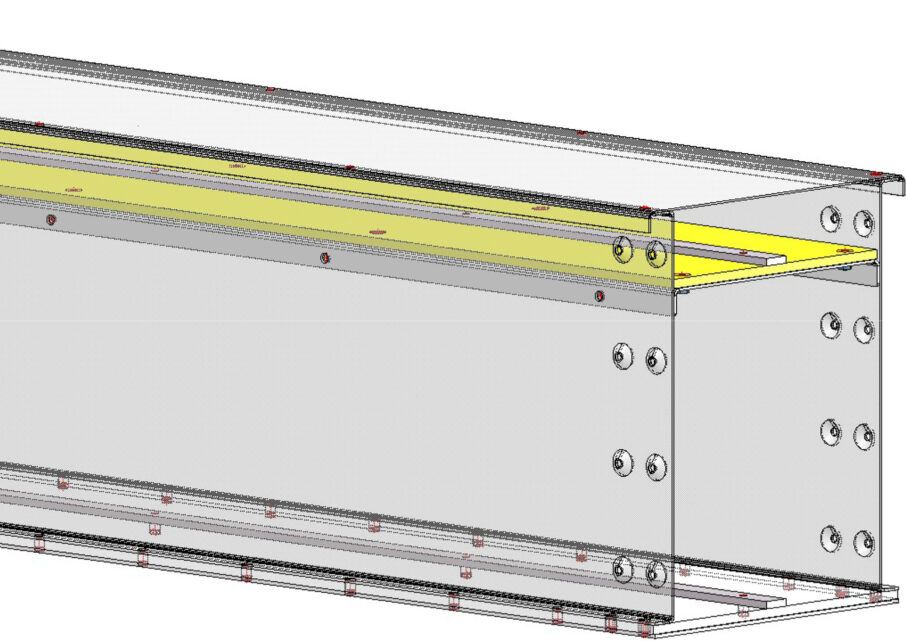

Trough chain conveyorBasic design

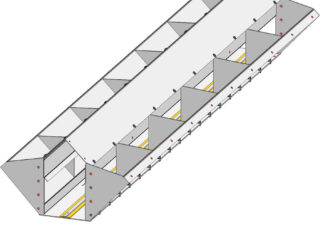

- Motor mounting platform with geared motor and flexible coupling

- Tensioning station and driving station, outside varnished and inside untreated, or hot-dip galvanised

- Troughs of strip-galvanised steel or outside varnished and inside untreated

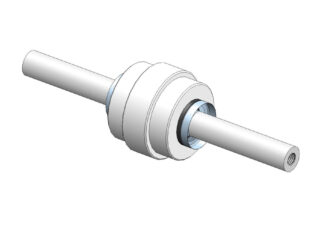

- Return rollers made of plastic (standard for KF240, KF315 and KF350) or ball-bearing return rollers made of steel (standard for KF440 and KF560)

- Wear rails made of highly wear-resistant steel, e.g. Hardox, guide rail made of St52. With plastic bottom no wear rail

- Conveyor chain according to DIN 8165 with single bent-back plates

Chain conveyor sizes and technical data

| Chain conveyor | KF240 | KF315 | KF350 | KF440 | KF560 | |

|---|---|---|---|---|---|---|

| Trough width | mm | 240 | 315 | 350 | 440 | 560 |

| Intended JACOB pipework Ø | mm | 200 | 250 | 300 | 350 | 350 |

| Capacity for grain 0.75 t/m³ | ||||||

| max. fill height | mm | 210 | 320 | 410 | 410 | 410 |

| Rated capacity at 0.5 m/s | t/h | 60 | 100 | 150 | 200 | 250 |

| Max. capacity at 0.5 m/s | t/h | 60 | 120 | 175 | 220 | 280 |

| Max. length at rated capacity | m | up to 59 | up to 58 | up to 38 | up to 36 | up to 28 |

| Speed at 0.5 m/s | rpm | 40 | 27 | 21 | 21 | 21 |

| Material thickness in the standard design | ||||||

| Base plate made of steel with plastic base, steel/plastic |

mm mm |

4 3/10 |

4 3/10 |

4 3/10 |

4 4/12 |

5 4/12 |

| Side plate | mm | 3 | 3 | 3 | 3 | 4 |

| Cover | mm | 2 | 2 | 2 | 2 | 3 |

| Chain |

||||||

| Chain breaking force | N | 90000 | 140000 | 140000 | 180000 | 180000 |

| Plates | mm | 35 x 5 | 45 x 6 | 45 x 6 | 50 x 8 | 50 x 8 |

| Chain pitch | mm | 125 | 125 | 160 | 160 | 160 |

| Chain wheel, number of teeth | 6 | 9 | 9 | 9 | 9 | |

| Weights of the elements with chain | ||||||

| Driving station without geared motor or material to be conveyed | kg | 118 | 181 | 316 | 546 | 763 |

| Tensioning station without material to be conveyed | kg | 71 | 117 | 168 | 265 | 362 |

| Trough empty | kg/m | 40 | 56 | 75 | 98 | 133 |

| Trough at max. fill height with grain 0.75 t/m³ | kg/m | 78 | 132 | 183 | 233 | 305 |

Chain conveyor design and accessories

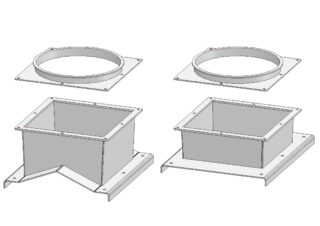

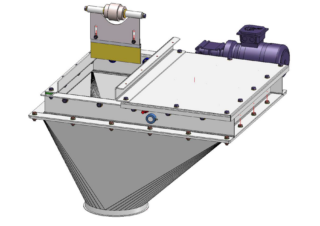

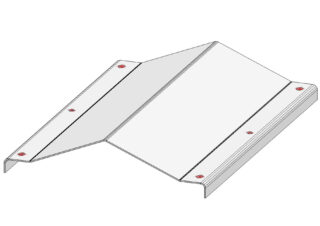

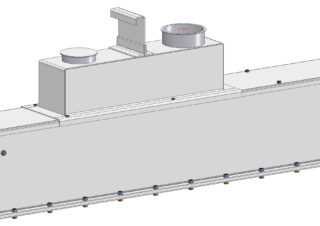

Inlet box for flat or roof-shaped cover

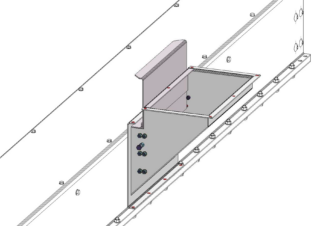

Side inlet with dosing valve

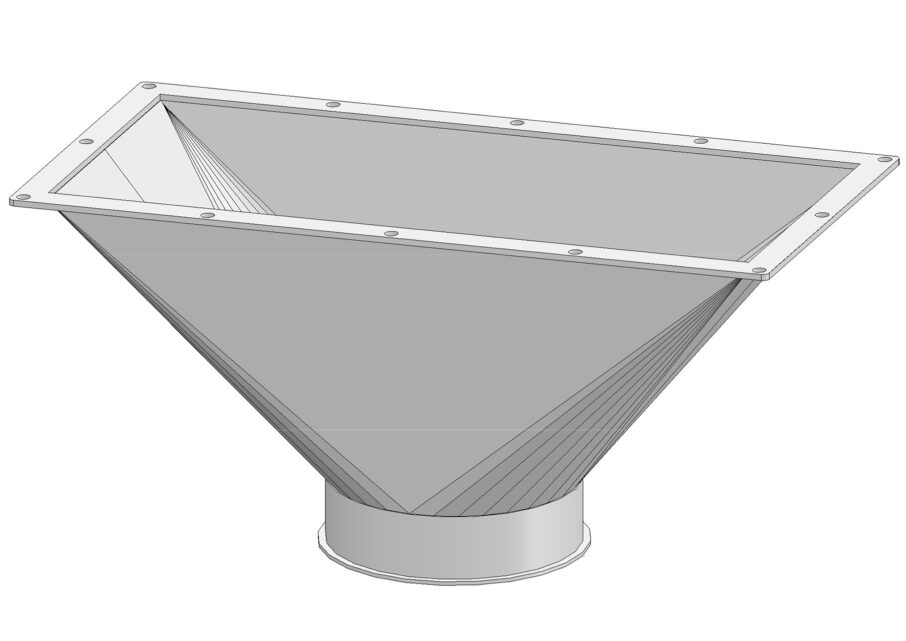

Intake trough

Spout for Jacob pipe system

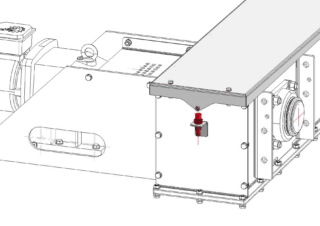

Spring-loaded cover for drive station with IFM IG511A inductive sensor and IFM EVC04A cable as overflow detector

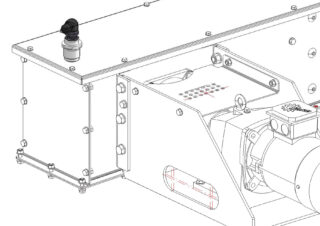

Capacitive sensor as full detector or overflow detector

Outlet slide gate (manual, electrical, pneumatical)

with scrapper brush for the chain

Spout under the whole valve for maximum cleanliness

Outlet slide gate (manual, electrical, pneumatical)

with scrapper brush for the chain

Spout under the outlet area

Loose counter flange for the whole slide gate

Loose counter flange for the outlet area

Roof-shaped cover

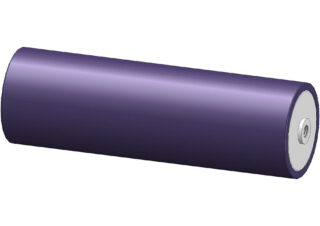

Plastic bottom

Inspection window

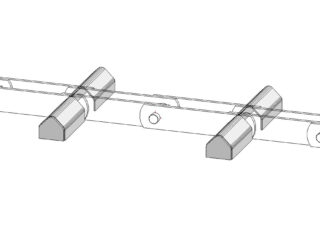

Return rollers made of white PE

Return rollers made of steel, rubberized

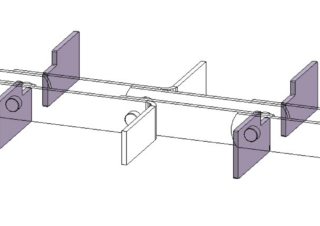

Conveyor chain according to DIN 8165 with single bent-back plates

Conveyor chain with extra raised link plates welded-on for inclined conveying

Return buckets

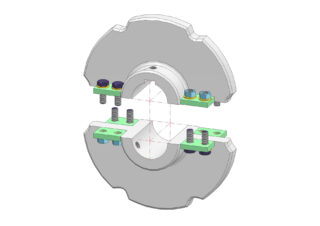

Divided chain wheel

Rain cover for geared motor

Reinforced tension unit for reversible direction of transport

Tension unit dead space reduced

Inlet for dosing via upper chain

Higher trough with intermediate bottom

Gear oil: mineral oil or synthetic (food compatible)

Tensioning station and driving station varnished or hot dip galvanized

Operating instructions

German or English

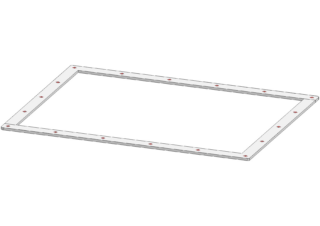

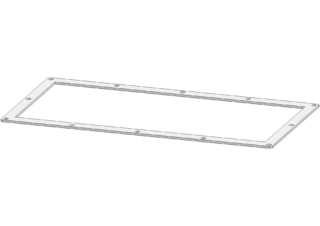

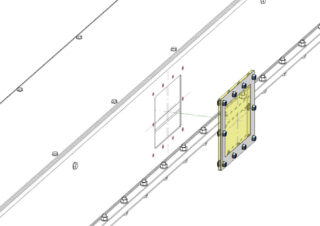

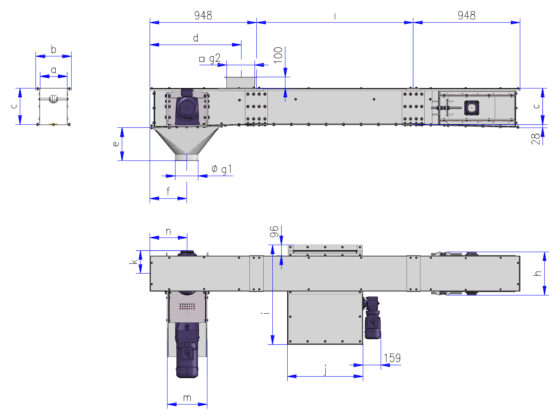

Dimension drawning for chain conveyors

The dimensions of our different chain conveyor types and their connecting dimensions are shown in the dimension drawing and the following table.

Chain conveyor types and dimensions

| KF240 | KF315 | KF350 | KF440 | KF560 | ||

|---|---|---|---|---|---|---|

| a | mm | 240 | 315 | 350 | 440 | 560 |

| b | mm | 317 | 392 | 427 | 517 | 637 |

| c | mm | 321 | 449 | 571 | 571 | 571 |

| d | mm | 810 | 810 | 952 | 952 | 952 |

| e | mm | 395 | 228 | 500 | 500 | 500 |

| f | mm | 327 | 327 | 357 | 357 | 357 |

| g1 | mm | Ø 200 | Ø 250 | Ø 300 | Ø 350 | arrangement |

| g2 | mm | 250 | 300 | 300 | 350 | arrangement |

| h | mm | 386 | 461 | 538 | 628 | 748 |

| i | mm | 885.5 | 1080 | 1025 | 1310 | - |

| j | mm | 672 | 672 | 1060 | 985 | - |

| k | mm | 204 | 252 | 285 | 360 | - |

| l | mm | 465 930 1240 1860 2480 2945 |

465 930 1240 1860 2480 2945 |

465 930 1240 1860 2480 |

465 930 1240 1860 2480 |

465 930 1240 1860 2480 |

| m | mm | 353 | 432 | 430 | 480 | - |

| n | mm | 332 | 332 | 357 | 357 | - |

Examples from our production

You might also be interested in

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Tags: Chain conveyorChain conveyorsConveying technologyProduct receptionTrough chain conveyors

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Login

Login