Product research made easy

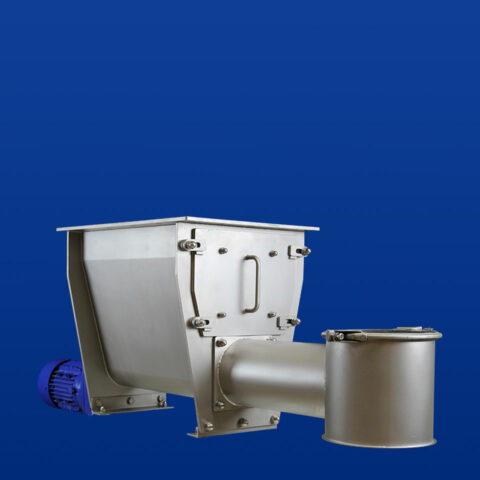

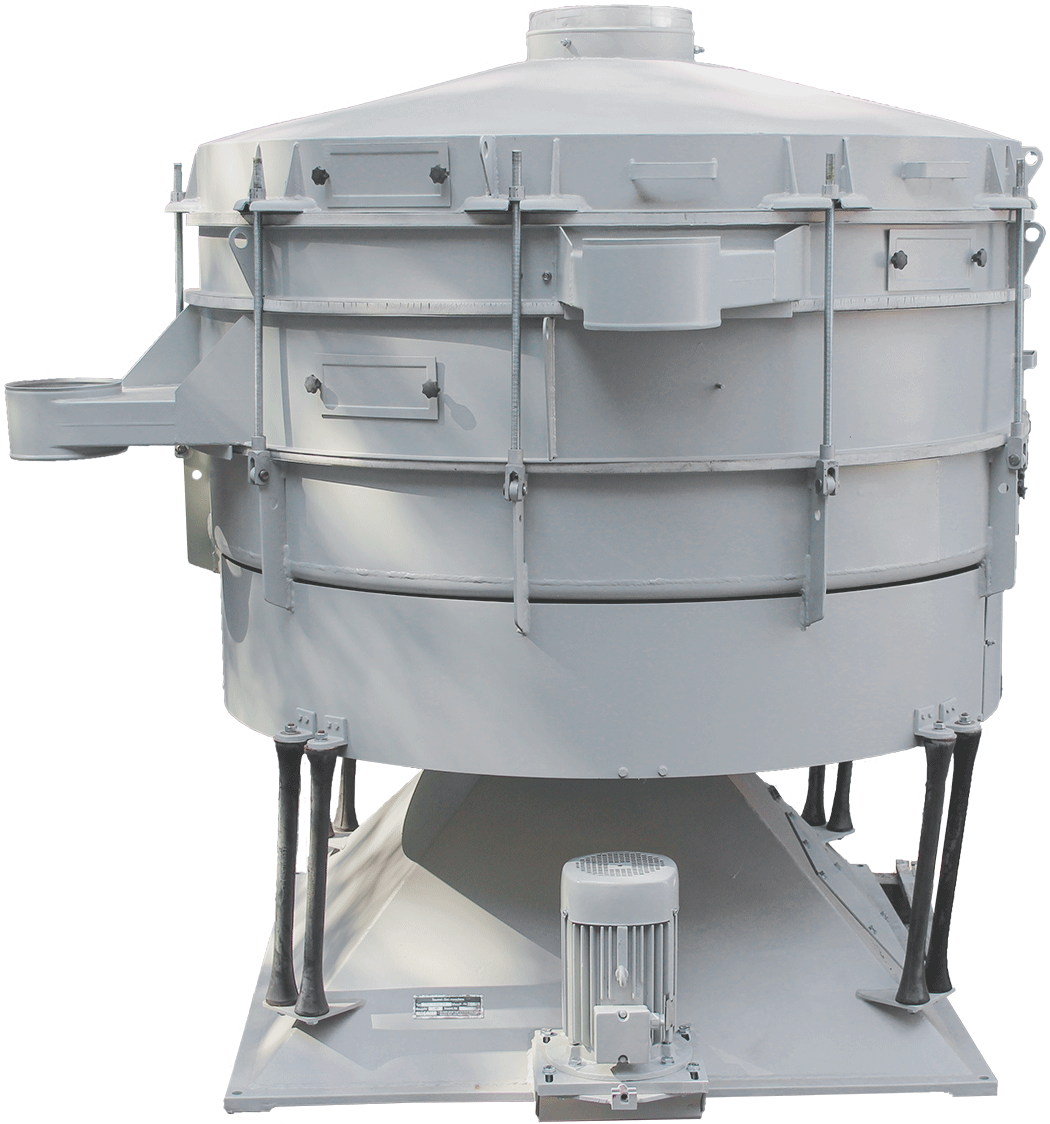

Screw conveyors, screw feeders, and screw dischargers;

chain conveyors, elevators, and grinders – we offer solutions for conveying and processing your products.

With our modular system, we can customise and expand our standard components for you.

Proven machines in high quality

Used machines

In our well-stocked used machinery warehouse you will find high-quality machines and components – often quickly available and ready for use.

Your one-stop shop

From the idea to the finished product

We focus on dialogue and teamwork and plan the overall concept together with you.

Planning, production, delivery, and assembly from a single source: for an uncomplicated flow and simple coordination of deadlines and interfaces.

Discover how we work on-site

From our production

Take a look at our machines and components in the standard versions and with common accessories.

PAUL GROTH – A tradition of mill construction

Mill and plant construction

Broad expertise, proximity to customers, and flexibility have been the factors for our success since 1930.

As a medium-sized family-owned company, we manufacture stand-alone machines and fit complete systems for handling and processing bulk materials today as we have done in the past.

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Login

Login