Lump crusher

for crushing of agglomerates and lumps

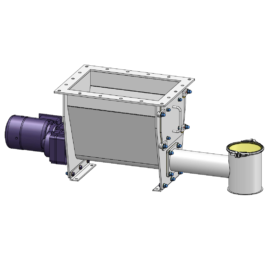

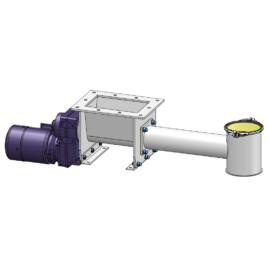

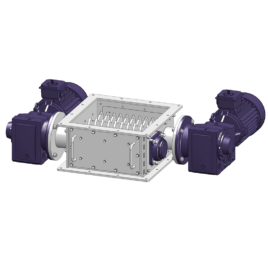

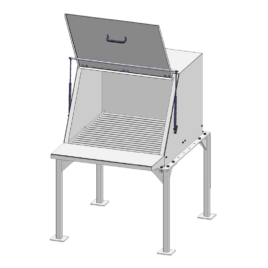

Whenever agglomerates and lumps in the food and chemical industry need to be eliminated and milled, the lump crushers MKB can be used. By means of slicing and grating they mill dry, brittle to slightly moist starting products into the desired final grain size. Thanks to its modular construction the lump crushers can be easily integrated into existing production lines or used as stand-alone devices.

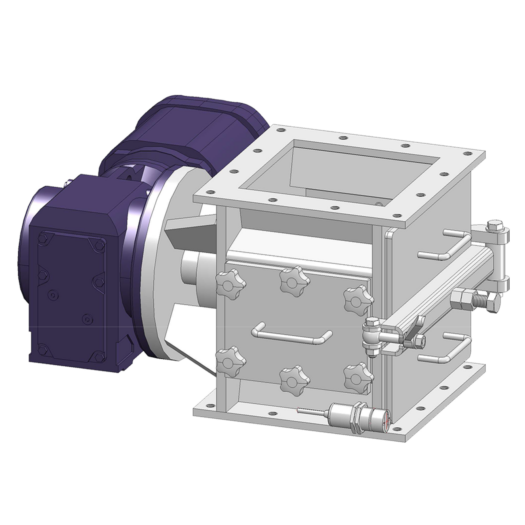

Lump crusherBasic design

- Very stable and largely dead space free construction

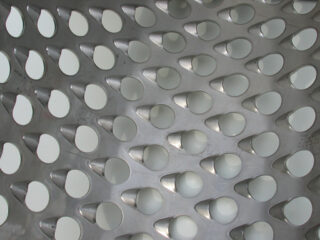

- Surface design: glass bead blasted

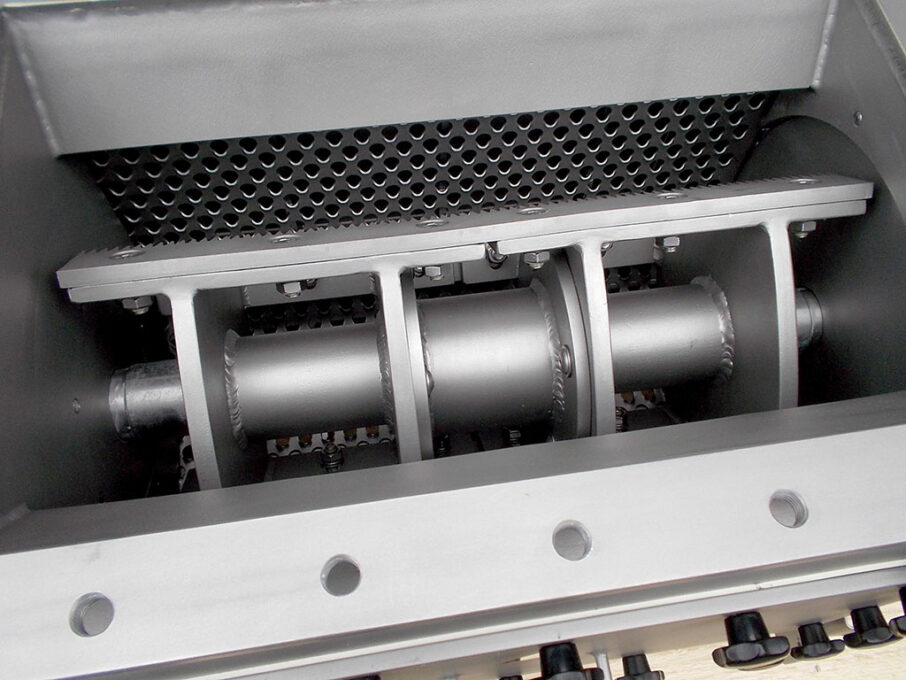

- Grating sieves with hole sizes from 2,5 to 16 mm

- Large openings for cleaning and inspection

- Shaft sealing with sealing rings or packing glands

Lump crusher sizes and technical data

| Type | Capacity l/h | flange inner mm | Length mm | Width mm | Height mm | Weight | Bearing |

|---|---|---|---|---|---|---|---|

| MKB 200 | 1500 | 200 x 200 | 1115 | 365 | 300 | 120 | 1x |

| MKB 400 | 6000 | 400 x 300 | 1550 | 400 | 450 | 280 | 2x |

| MKB 500 | 13000 | 500 x 300 | 1650 | 400 | 450 | 390 | 2x |

Function

The clumped and hardened bulk goods are fed into the lump crusher through the inlet using gravity. The rotor blades rotate, press the product through a grating sieve and mill the agglomerates to the desired final grain size.

Areas of use

- Reduction of grain size

- Milling after emptying of big bags and sacks

- Milling prior to pneumatic transportation

- Milling prior to mixing

- Milling of filter cakes

- Milling of broken goods and goods for reworking

Characteristics

- No additional sieving of coarse material is required

- Quick and easy replacement of the grating sieve

- Low peripheral speed for gentle milling

- Easy to clean

Options

- Material: stainless steel 1.4301, 1.4571, othersteel

- Surface finish: glass bead blasted to highly polished

- Chassis, control unit, inlet and outlet hopper, transition pieces (round to square)

- Various sizes up to max. 13 m³/h, other sizes on reques

Examples of production

You might also be interested in

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Tags: CrusherLump crusherLump shredderMANCONProduct crushingShredder

Login

Login