Rotary valves (cast)

also suitable for pneumatic conveying systems

Rotary valvesBasic design

- Suitable for use in pneumatic conveying systems

- various types of rotors

- Tight tolerances

- Good tightness

- made of in cast iron or stainless steel AISI316

- with direct drive or chain drive incl. chain guard

Types of rotary valves in cast design

Technical data for rotary valve type VPS

The drop through rotary valve type “VPS” has been studied and manufactured for the feeding and unloading of any kind of product in grains or powder. It is used in pneumatic conveying lines, mounted under a cyclone or at the fi lter exhaust. Manufactured in cast iron, nickel / chromium plated cast iron or stainless steel AISI316.

Thanks to its low tolerances and several type of rotors, it can fit any type of product or special requirement of the customer. The valve is available with gearmotor or chain drive with chain guard according to CE rules.

| Type VPS | VPS180 | VPS230 | VPS270 | VPS300 | VPS350 | VPS400 | |

|---|---|---|---|---|---|---|---|

| Inlet | mm | Ø 120 | Ø 150 | Ø 180 | Ø 220 | Ø 300 | Ø 350 |

| Outlet | mm | 150 x 120 | 185 x 148 | 242 x 180 | 266 x 218 | 360 x 250 | 400 x 320 |

| Height | mm | 245 | 310 | 340 | 382 | 470 | 527 |

| Capacity vol. | l/U | 2 | 4.5 | 8 | 12 | 25 | 40 |

| Number of rotor blades | 6 | 8 | 8 | 8 | 8 | 8 | |

| Speed | rpm | 32 | 32 | 31 | 32 | 31 | 30 |

| Power | kW | 0.37 | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 |

| Weight without drive | kg | 30 | 46 | 72 | 90 | 167 | 215 |

| Weight with chain drive approx. | kg | 53 | 70 | 110 | 130 | 240 | 285 |

| Max differential of pressure | bar | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

Recommended filling depending on product flow properties

| Speed | < 10 rpm | 11 - 20 rpm | 21 - 30 rpm | >30 rpm |

|---|---|---|---|---|

| Free flowing | 90% | 80% | 70% | 60% |

| Flowing | 80% | 70% | 60% | 50% |

| Poorly flowing | 70% | 60% | 50% | 40% |

| Very poorly flowing | 60% | 50% | 40% | 35% |

Technical data for rotary valve type VPR

The drop through rotary valve type “VPR” is born like a synthesis of the “VPS” valves /having the same body) and the “RS”. It is particularly suitable for the feeding and pneumatic conveying of products in grain and powder and it can be used in all industrial sectors involving pneumatic conveying lines with average / low pressure.

For the particular construction and the minimum tolerances, it ensures excellent airlock and good fl owing of the product. The characteristic circular fl ange allows an easy interlock with feeding bins. Manufactured in cast iron, nickel / chromium plated cast iron or stainless steel AISI316, it is supplied with bare shaft or motorization consisting in variable speed gearmotor or gearmotor and complete drive with chain guard according to CE rules.

| Type VPR | VPR180 | VPR230 | VPR270 | VPR300 | VPR350 | VPR400 | |

|---|---|---|---|---|---|---|---|

| Inlet | mm | Ø 120 | Ø 150 | Ø 180 | Ø 220 | Ø 300 | Ø 350 |

| Outlet | mm | 150 x 120 | 185 x 148 | 242 x 180 | 266 x 218 | 360 x 250 | 400 x 320 |

| Height | mm | 245 | 310 | 340 | 382 | 470 | 527 |

| Capacity vol. | l/U | 3 | 6 | 11 | 17 | 30 | 45 |

| Number of rotor blades | 8 | 8 | 8 | 8 | 8 | 10 | |

| Speed | rpm | 32 | 31 | 32 | 32 | 31 | 34 |

| Power | kW | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 |

| Weight without drive | kg | 31 | 51 | 76 | 95 | 167 | 218 |

| Weight with chain drive approx. | kg | 61 | 82 | 113 | 158 | 244 | 295 |

| Max differential of pressure | bar | 1 | 1 | 1 | 1 | 1 | 1 |

Recommended filling depending on product flow properties

| Speed | < 10 rpm | 11 - 20 rpm | 21 - 30 rpm | >30 rpm |

|---|---|---|---|---|

| Free flowing | 90% | 80% | 70% | 60% |

| Flowing | 80% | 70% | 60% | 50% |

| Poorly flowing | 70% | 60% | 50% | 40% |

| Very poorly flowing | 60% | 50% | 40% | 35% |

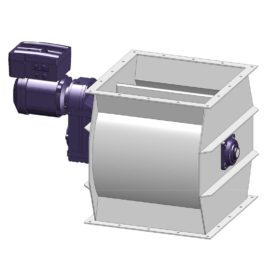

Technical data for rotary valve type RS

The drop through rotary valve type “RS” is particularly suitable for the feeding and pneumatic conveying of products in grain and powder and it can be used in all industrial sectors involving pneumatic conveying lines with average / low pressure. For the particular construction the several type of rotors and the minimum tolerances, it ensures excellent airlock and good fl owing of the product in pneumatic conveying lines.

This valve has been studied to fi t any type of product or special requirement of the customer. Manufactured in cast iron, nickel / chromium plated cast iron or stainless steel AISI316, it is supplied with bare shaft or motorization consisting in variable speed gearmotor or gearmotor and complete drive with chain guard according to CE rules.

| Type RS | RS180 | RS230 | RS270 | RS300 | RS350 | RS450 | |

|---|---|---|---|---|---|---|---|

| Inlet | mm | 190 x 118 | 238 x 135 | 276 x 148 | 340 x 198 | 470 x 238 | 570 x 285 |

| Outlet | mm | 190 x 118 | 235 x 135 | 276 x 158 | 340 x 198 | 476 x 220 | 570 x 285 |

| Height | mm | 270 | 330 | 390 | 447 | 530 | 677 |

| Capacity vol. | l/U | 4 | 8 | 12 | 20 | 40 | 80 |

| Number of rotor baldes | 8 | 8 | 8 | 8 | 10 | 10 | |

| Speed | rpm | 32 | 31 | 32 | 31 | 30 | 30 |

| Power | kW | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 |

| Weight without drive | kg | 38 | 55 | 95 | 130 | 238 | 465 |

| Weight with chaindrive approx. | kg | 67 | 97 | 135 | 190 | 318 | 575 |

| Max differential of pressure | bar | 1 | 1 | 1 | 1 | 1 | 1 |

Recommended filling depending on product flow properties

| Speed | < 10 rpm | 11 - 20 rpm | 21 - 30 rpm | >30 rpm |

|---|---|---|---|---|

| Free flowing | 90% | 80% | 70% | 60% |

| Flowing | 80% | 70% | 60% | 50% |

| Poorly flowing | 70% | 60% | 50% | 40% |

| Very poorly flowing | 60% | 50% | 40% | 35% |

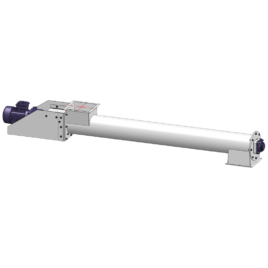

Technical data for rotary valve type SF

The blow through rotary valve type “SF” is particularly suitable for the feeding and pneumatic conveying of products in grain and powder and it can be used in all industrial sectors involving pneumatic conveying lines with average / low pressure. For the particular construction the several type of rotors and the minimum tolerances, it ensures excellent airlock and good fl owing of the product in pneumatic conveying lines.

This valve has been studied to fi t any type of product or special requirement of the customer. Manufactured in cast iron, nickel / chromium plated cast iron or stainless steel AISI316, it is equipped with fl ange connections on both sides and it is available with bare shaft or motorization consisting in variable speed gearmotor or gearmotor and complete drive with chain guard according to CE rules.

| Type SF | SF180 | SF230 | SF270 | SF300 | SF350 | SF450 | |

|---|---|---|---|---|---|---|---|

| Inlet | mm | 190 x 118 | 238 x 135 | 276 x 148 | 340 x 198 | 470 x 238 | 570 x 285 |

| Clear blow-through diameter | mm | 54 | 65 | 74 | 96 | 118 | 150 |

| Height | mm | 270 | 330 | 390 | 447 | 530 | 677 |

| Capacity | l/U | 4 | 8 | 12 | 20 | 40 | 80 |

| Number of rotor blades | 8 | 8 | 8 | 8 | 10 | 10 | |

| Speed | rpm | 32 | 31 | 32 | 31 | 30 | 30 |

| Power | kW | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 |

| Weight without drive | kg | 42 | 65 | 100 | 145 | 255 | 490 |

| Weight with chain drive approx. | kg | 70 | 96 | 139 | 205 | 335 | 600 |

| Max differential of pressure | bar | 1 | 1 | 1 | 1 | 1 | 1 |

Recommended filling depending on product flow properties

| Speed | < 10 rpm | 11 - 20 rpm | 21 - 30 rpm | >30 rpm |

|---|---|---|---|---|

| Free flowing | 90% | 80% | 70% | 60% |

| Flowing | 80% | 70% | 60% | 50% |

| Poorly flowing | 70% | 60% | 50% | 40% |

| Very poorly flowing | 60% | 50% | 40% | 35% |

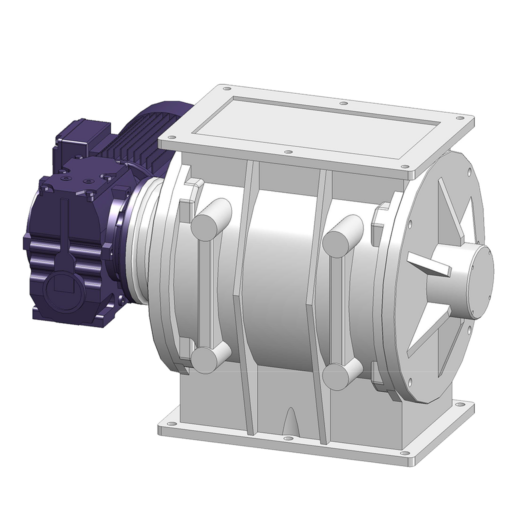

Technical data for rotary valve type UPR

The "UPR" rotary valve is particularly suitable for the dosing and pneumatic transportation of granular, flaky or ground products. Thanks to its sturdy construction and flanging unified according to UNI PN10 standards (DIN 2576 ND10) or ANSII50 standards it is particularly suitable for use in both heavy industry and in the chemical and plastic industrial fields.

The special confirmation of the entrance inlet and a series of other technical adaptations reduce the risk of the pinching of the product between the blade and stator in cases in which particularly different products need to be discharged. The external bearing slots and the packing PTFE packing gland sealing system, provide further guarantees of rational performance and also make it possible to use the valve at high temperatures.

| Type UPR | UPR200 | UPR250 | UPR300 | |

|---|---|---|---|---|

| Inlet | Ø mm | 200 | 250 | 300 |

| Outlet | Ø mm | 200 | 250 | 300 |

| Height | mm | 400 | 500 | 580 |

| Capacity vol. | l/U | 8 | 18 | 38 |

| Number of rotor blades | 10 | 10 | 10 | |

| Speed | rpm | as required | as required | as required |

| Power | kW | as required | as required | as required |

| Weight without drive | kg | 110 | 180 | 230 |

| Weight with chain drive approx. | kg | 165 | 240 | 334 |

| Max differential of pressure | bar | 1 | 1 | 1 |

Recommended filling depending on product flow properties

| Speed | < 10 rpm | 11 - 20 rpm | 21 - 30 rpm | >30 rpm |

|---|---|---|---|---|

| Free flowing | 90% | 80% | 70% | 60% |

| Flowing | 80% | 70% | 60% | 50% |

| Poorly flowing | 70% | 60% | 50% | 40% |

| Very poorly flowing | 60% | 50% | 40% | 35% |

You might also be interested in

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Tags: Air technologyBlow through rotary valvesDedustingPneumatic conveyingRotary valvesValve for discharge

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Login

Login