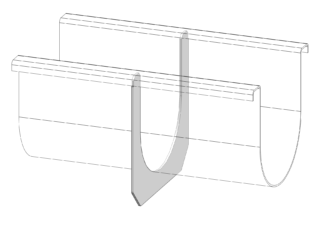

Trough screw conveyors

for the mechanical conveying of bulk materials

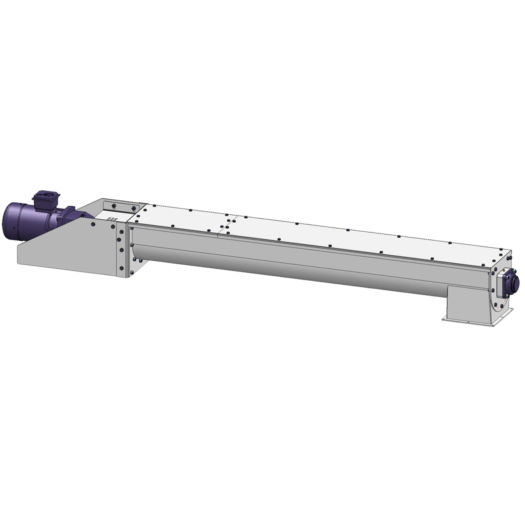

PAUL GROTH trough screw conveyors for horizontal or slightly ascending mechanical conveying of floury, granular and lumpy bulk materials in the food, grain and non-food industries. With the appropriate design, the trough screw conveyors can also be used for dosing, wetting, mixing or crushing of bulk materials.

For use in the food industry, all surfaces inside and outside are accessible and easy to clean. All materials and substances that come into contact with the product are suitable for food contact.

Starting with our standard modular-system we adapt the trough screw conveyor to the product properties, the installation option and other process requirements.

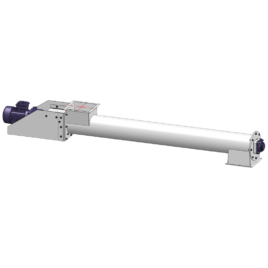

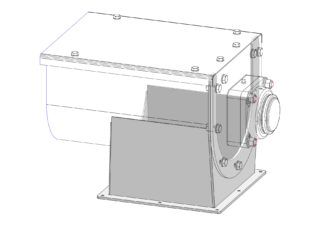

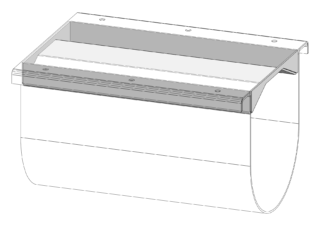

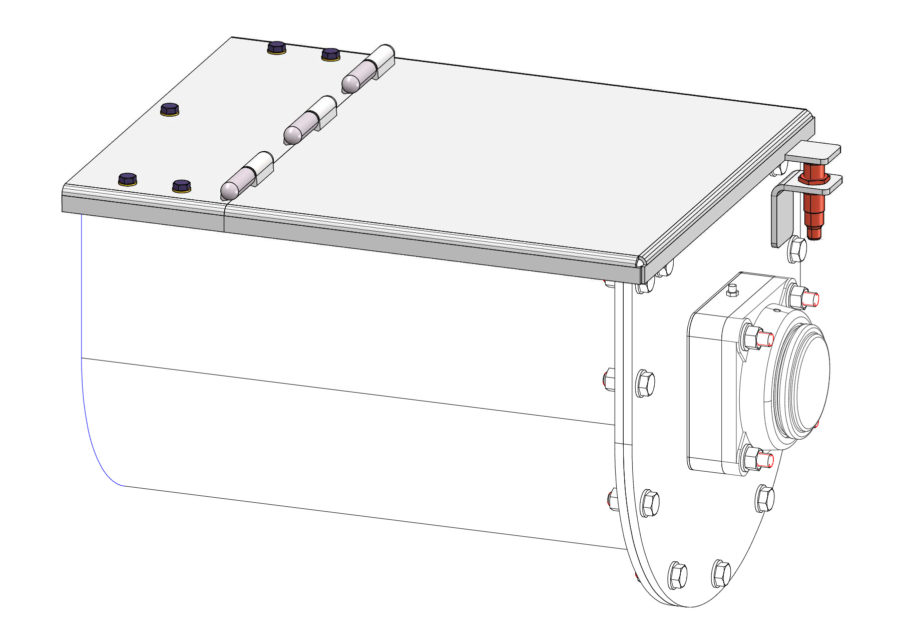

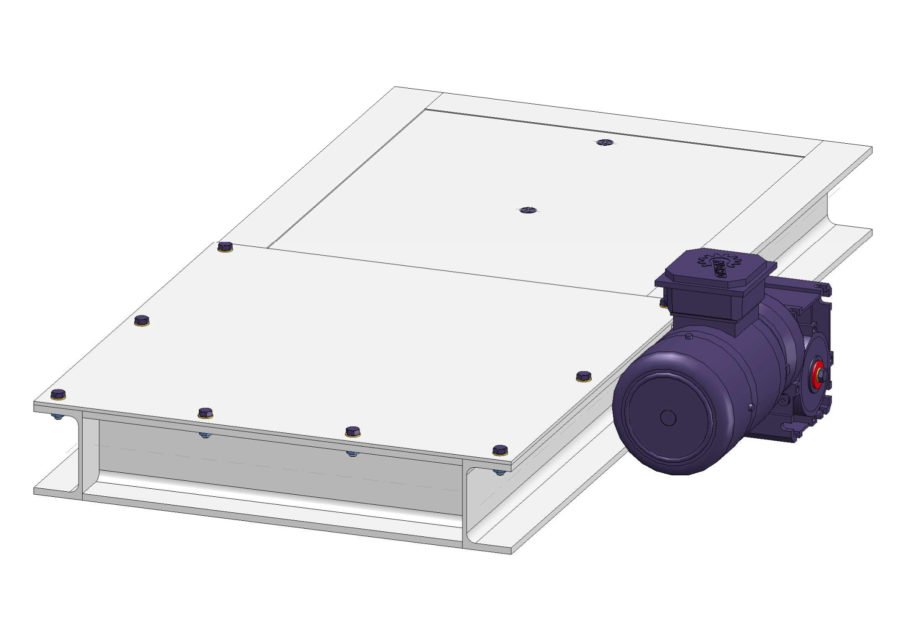

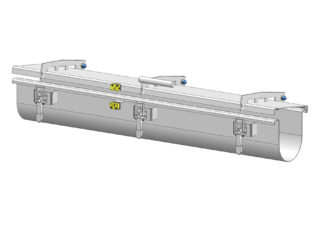

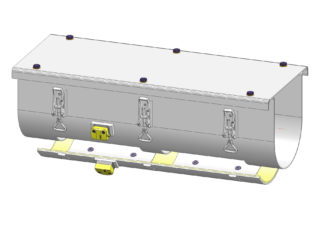

Trough screw conveyor

Basic design

- Motor bracket with geared motor and flexible coupling

- Trough screw conveyors made of steel: outside painted and inside untreated, or trough hot-dip galvanised

- Trough screw conveyors made of stainless steel: bath pickled and outside glass-bead blasted

- Screw thread made of highly wear-resistant steel too

- Preferred sizes TS170, TS220 TS270 and TS320

Trough screw conveyor sizes and technical data

| Tubular screw conveyor | TS100 | TS120 | TS170 | TS220 | TS270 | TS320 | TS370 | TS420 | |

|---|---|---|---|---|---|---|---|---|---|

| Trough width | mm | 100 | 120 | 170 | 220 | 270 | 320 | 370 | 420 |

| Thread diameter | mm | 90 | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

| Intended JACOB pipework Ø | mm | 120 150 |

120 150 |

150 200 |

200 | 200 250 |

250 300 |

300 | 300 |

| Capacity example depending on product properties and requirements of the process | |||||||||

| Grain 0.75 t/m³ | t/h | 2 | 4 | 16 | 30 | 45 | 65 | 90 | 115 |

| Powder 0.5 t/m³ | t/h | 0.5 | 1 | 4 | 8 | 13 | 17 | 23 | 30 |

| Material thickness in the standard design | |||||||||

| Trough |

mm | 2.0 | 2.0 | 3.0 (VA 2.0 mm) | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Thread inner/outer Steel Stainless steel |

mm mm |

- - |

- - |

3/1.6 3/1.6 |

6/3 3.5/1.7 |

6/3 - |

6/3 - |

5/2.5 - |

8/4 - |

| Screw flights Steel Satinless steel |

mm mm |

3 3 |

3 3 |

5 4 |

5 4 |

5 4 |

5 4 |

6 5 |

6 5 |

Trough screw conveyors design and accessories

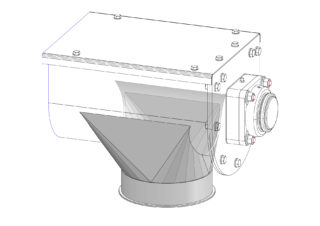

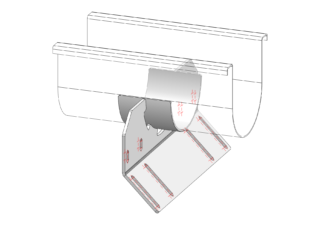

Angular outlet suitable for

Jacob transition piece

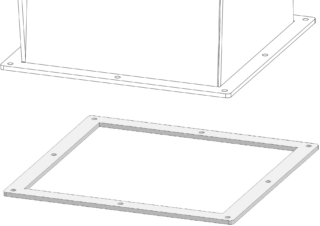

Loose counterflange for outlet

Round outlet to Jacob pipework system

Dosing plate for trough screw conveyor

Dosing saddle for trough screw conveyor

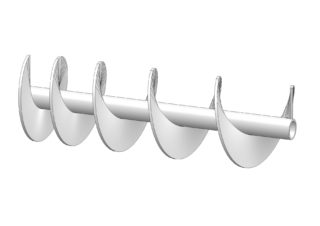

Progressive thread pitch

Paddle threadwith paddles screwed in

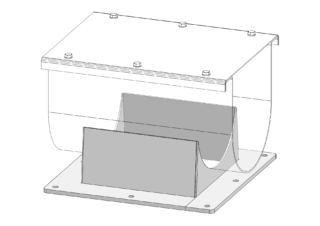

Overflow valve

with safety switch

Inside overflow valve

Capacitive sensor

Weld-on socket for intermediate discharge valve

Outlet slide gate manually, electrically or pneumatically operated

Hand outlet slide

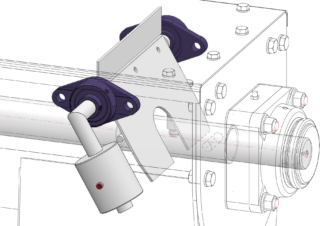

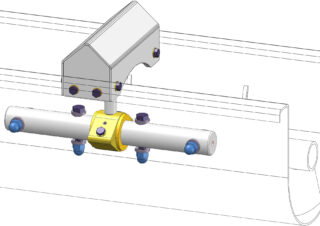

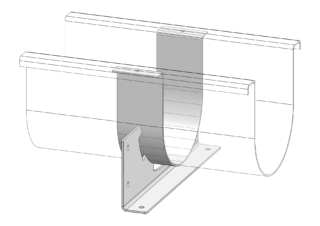

Two-part intermediate bearing

for trough screw conveyor

Roof over intermediate bearing

for long inlet

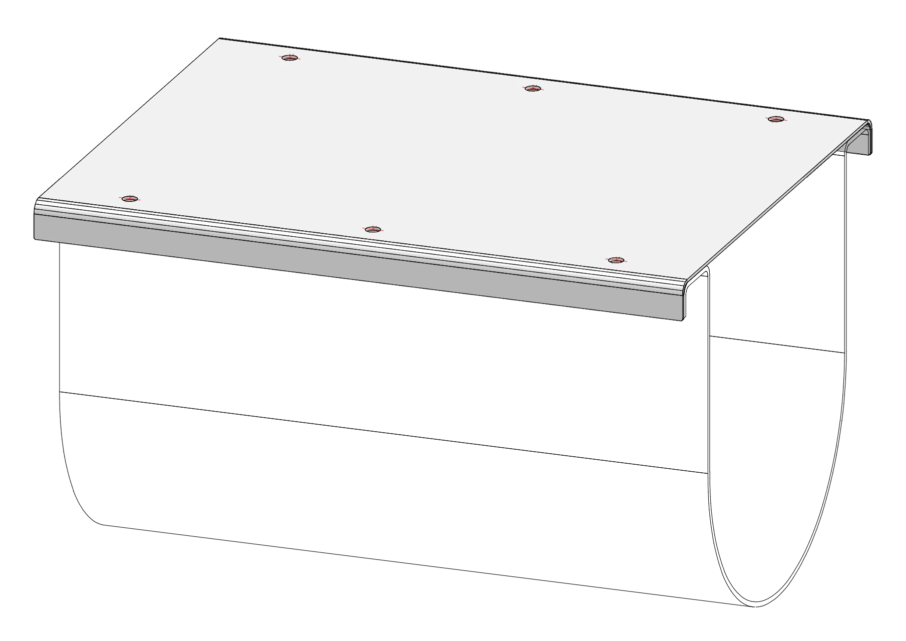

Flat cover for trough screw conveyor

Divided trough

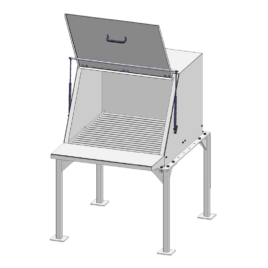

Hinged cover with safety switch

Hinged bottom with safety switch

Rain cover for geared motor

Welded on holding plate

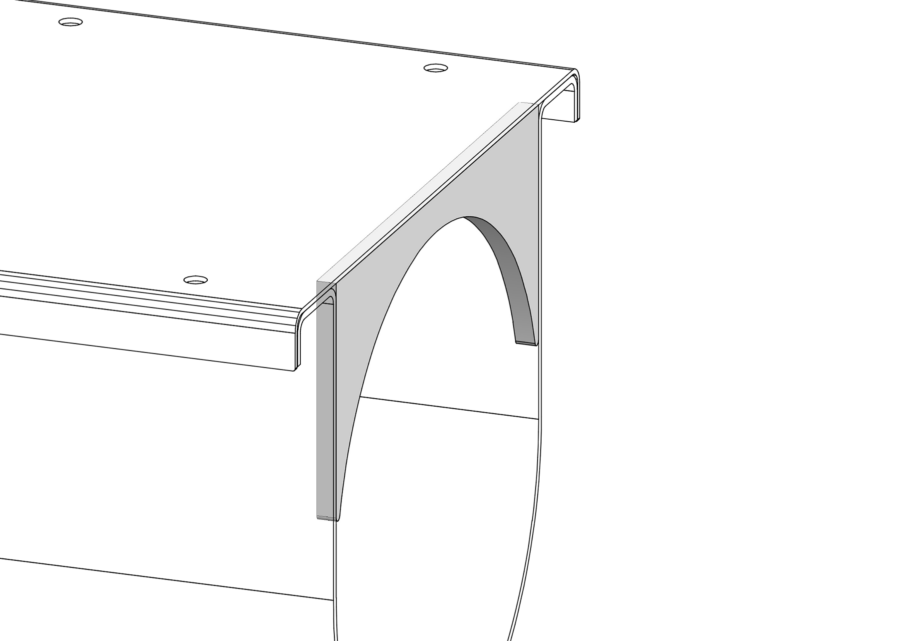

Foot with half shell for trough

Rib as trough reinforcement

Speed control

Version for dry food

ATEX zone 22 and 21

Operating instructions

German or English

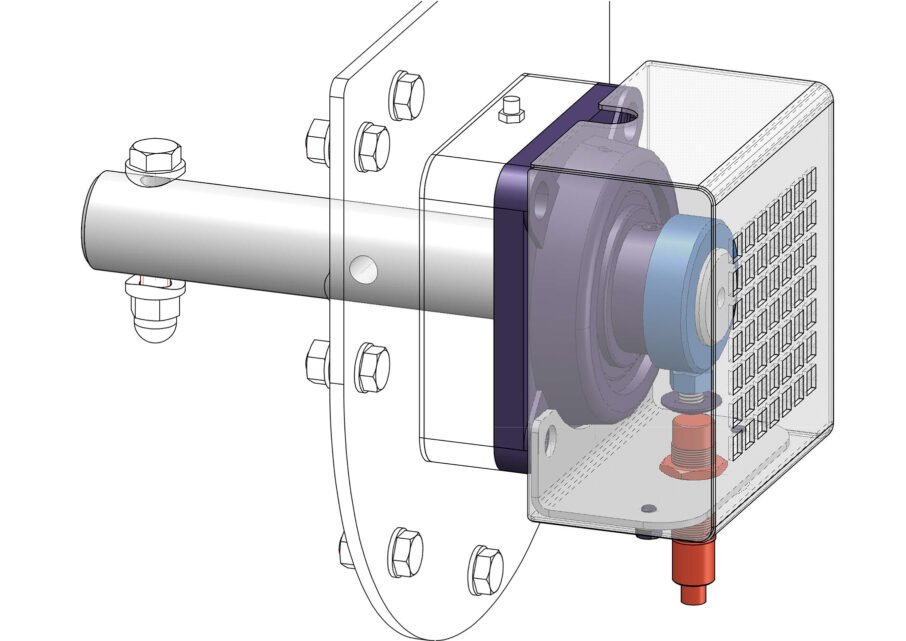

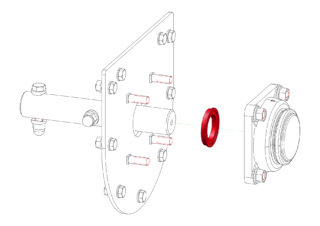

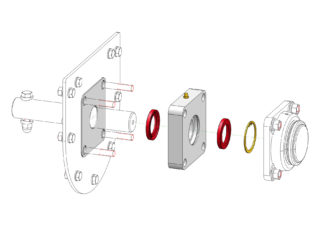

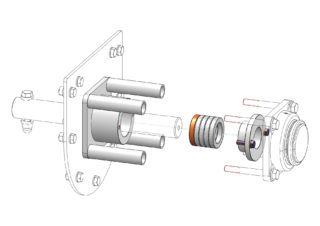

Shaft sealing for screw conveyors

The shaft seals of our screw conveyors can optional be constructed according to the conditions of use. Well established versions are shown in the table below. The shaft sealing rings are available for food and non-food.

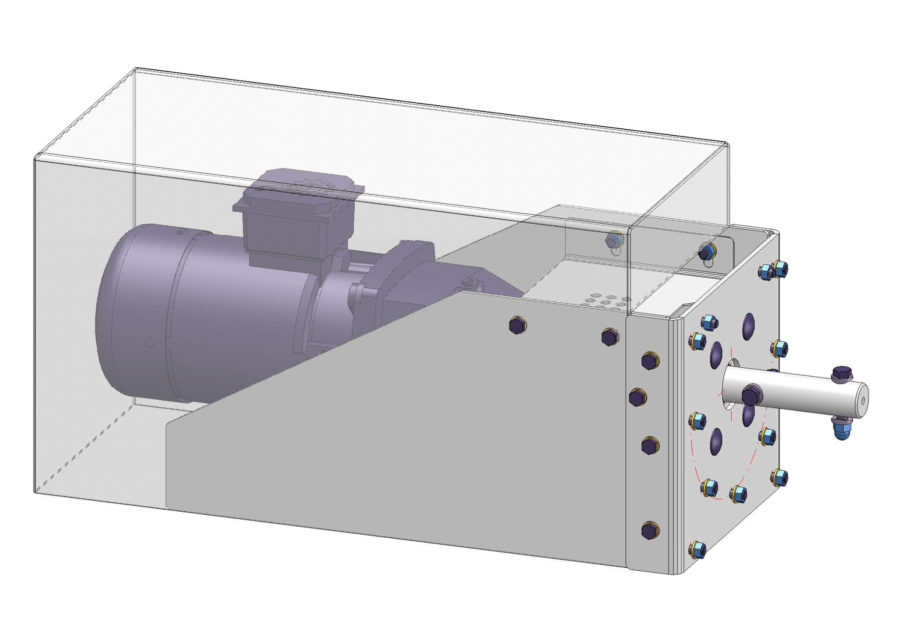

HP shaft seals flush with end plate

Aluminium housing with two shaft sealing rings and grease block or flushing air connection

Shaft sealing with stuffing box

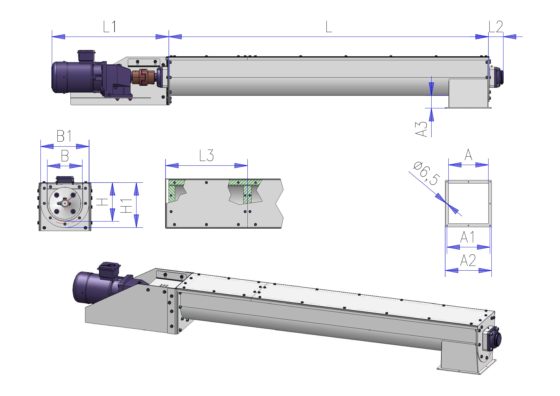

Dimension drawing for trough screw conveyors

The dimensions of our different trough screw conveyor types and their connecting dimensions are shown in the dimension drawing and the following table.

Dimensions of trough screw conveyors

| TS170 | TS220 | TS270 | TS320 | ||

|---|---|---|---|---|---|

| A | mm | 180 (250) | 250 | (250) 300 | (300) 350 |

| A1 | mm | 202 (270) | 270 | (270) 325 | (325) 375 |

| A2 | mm | 220 (290) | 290 | (290) 345 | (345) 375 |

| A3 | mm | 68 (69) | 80 | 62 (62) | (68) 68 |

| B | mm | 170 | 220 | 270 | 320 |

| B1 | mm | 242 | 302 | 360 | 412 |

| H | mm | 195 | 243 | 287 | 335 |

| H1 | mm | 229 | 281 | 329 | 378 |

| L | mm | - | - | - | - |

| L1 | mm | - | - | - | - |

| L2 | mm | - | - | - | - |

| L3 | mm | 500 | 500 | 750 | 750 |

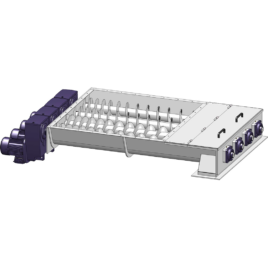

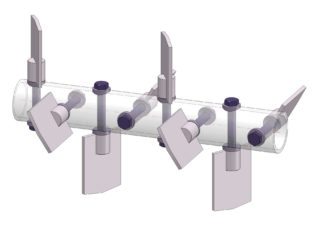

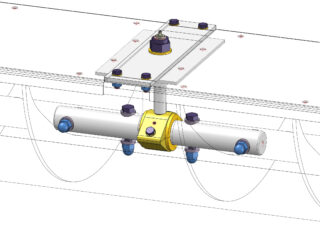

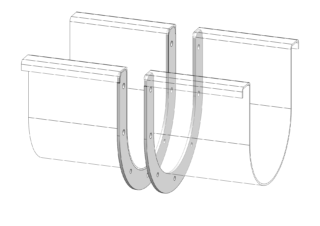

Multiple trough screw conveyors

Trough screws can be designed as multiple screw conveyors to discharge heavy flowing products over a larger area from a silo or when site conditions require low headroom.

Examples from our production

You might also be interested in

How to contact us

Phone +49 4121-7957-0

Fax +49 4121-7957-79

eMail e-mail@paul-groth.com

Contact us

Use the contact form or email, and the right employee will contact you directly.

Tags: Conveying technologyDischargeScrew conveyorScrew conveyorsTrough screw conveyorsTrough screw feeder

Login

Login